The use of automated hydraulic presses has transformed manufacturing and production processes across several industries. From the automotive industry to aerospace and beyond, these machines play a critical role in shaping, bending, and cutting materials with unmatched precision and consistency. However, not all hydraulic presses are created equal. The quality of an automated hydraulic press hinges on several features that can impact productivity, safety, and overall operational efficiency.

Here are six key features to consider when evaluating the quality of an automated hydraulic press:

Advanced Control Systems

A top-quality automated hydraulic press should have a sophisticated control system capable of supporting complex tasks. This includes features like programmable logic controllers (PLCs), touchscreen operator interfaces, and digital readouts for precision control. These elements enable operators to program the machine to execute precise, repetitive tasks with minimal variance.

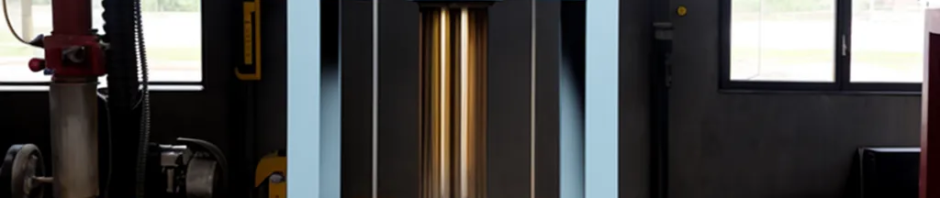

High-Quality Components

The overall durability and lifespan of a hydraulic press are largely dependent on the quality of its components. High-quality cylinders, frames, pumps, valves, and seals are essential for a long-lasting, efficient machine. These components need to withstand high pressures and temperatures while maintaining precise movements. Additionally, they should require minimal maintenance to keep the hydraulic press running smoothly over time.

Safety Features

The safety of operators should always be a priority in any manufacturing setting. A good automated hydraulic press should have safety measures in place such as overload protection, emergency stop buttons, light curtains, safety guards, and interlocks. These features can prevent accidents and protect operators from potential harm while ensuring the machine’s longevity.

Energy Efficiency

Energy efficiency is increasingly important in today’s manufacturing environment. An automated hydraulic press that operates with high energy efficiency not only reduces operational costs but also aligns with environmentally friendly practices. Look for machines with advanced hydraulic systems and electric drive technology that minimize energy consumption.

Flexibility and Adaptability

A good automated hydraulic press should be flexible and adaptable to accommodate a variety of tasks. This includes different press capacities, changeable die setups, adjustable speed, and pressure control, among other factors. This flexibility allows the machine to adapt to different manufacturing requirements, making it a versatile tool in any production process

Read more here about some of the best automated hydraulic presses in the market.